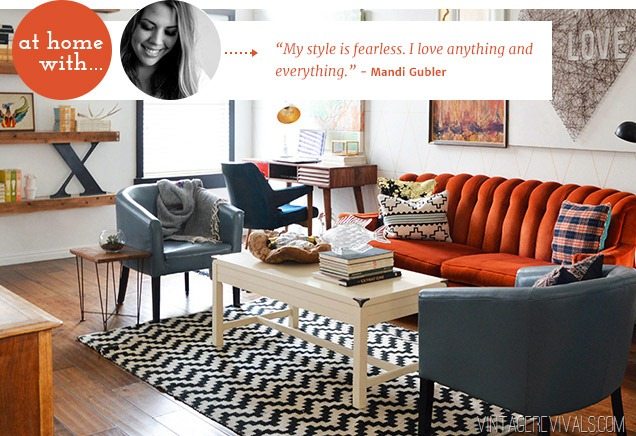

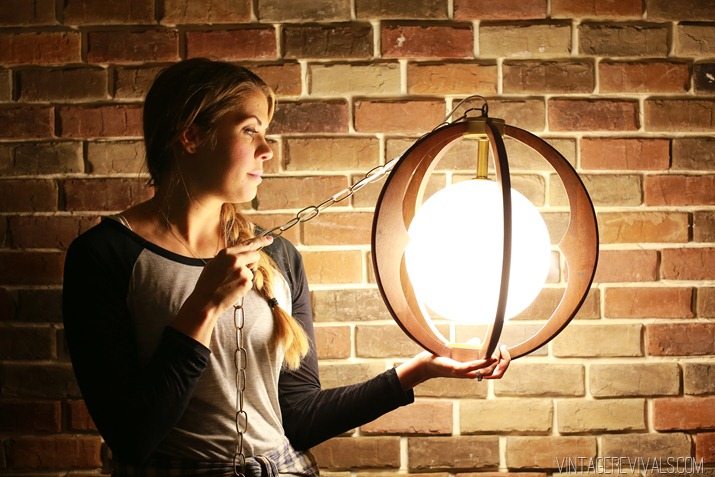

Building lights is sort of my thing. It is honestly my DIY spirit animal. That being said this light pushed me to the brink. Not because it is hard, but because I was trying to figure out the best way to do it in the most uncomplicated way possible (which complicates things). So after trying out 3 different types of wires and few hardware swaps I am SO excited to share with you the most simplified version of this brass bent arm chandelier!

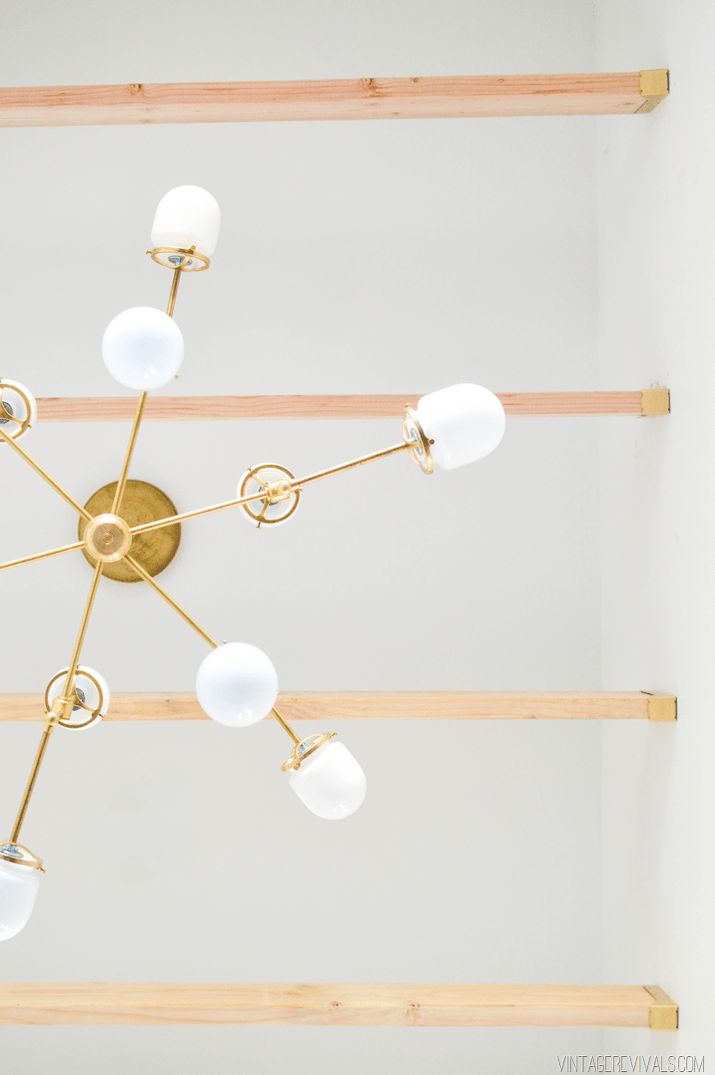

A few weeks ago I was thumbing through a magazine and came across this gorgeous light from Circa lighting. I loved all of the different angles and the whole feel of it. I also love Lindsay Adelman and her branch lights so hard. I knew that I could use both of them as a jumping off point for an amazing light in the entryway.

After spending a few hours on Grand Brass looking at all of the parts that they had, and a lot of sketching I came up with a plan (and ended up with a lot of parts.) All of the serial numbers for the parts are listed after their description.

a. (12) 8in. X 1/8 IPS HOLLOW BRASS PIPE STEM (PIBR08-0X8)

b. (12) 6in. X 1/8 IPS HOLLOW BRASS PIPE STEM (PIBR06-0X8)

c. (6) 1/8F sides X 1/8F bottom X 1/8F top SMALL CLUSTER BODY (BOS2X8)

d.(12) 3-1/4in. SPOKED HOLDER CAST BRASS with 1/8F TAPPED HOLE (HO3-1/4S)

e.(12) PORCELAIN SOCKET (SO10045C)

f. (1)1/8F sides X 1/4F bottom X 1/8F top JUMBO CLUSTER BODY (BOJ6)

g. (3)* 12in. X 1/8 IPS HOLLOW BRASS PIPE STEM (PIBR12-0X8)

h. (1) 1/4IPS PIPE PENDANT HANGING CROSS BAR SET (CB208)

i. (6) 1/8F X 1/8F ips. ADJUSTABLE FRICTION SWIVEL (SV140)

j. (2)* 1/8F THRU 5/8H X 5/8W STRAIGHT COUPLING (NE438)

k. (1) 1/4 PLUG WITH SCREW DRIVER SLOT (FI1/4PLUG)

l. (6) 1/8 PLUG WITH SCREW DRIVER SLOT (FI1/8PLUG)

m. (1) 8in. BRASS FLAT BASE W/RETURN (BAFL08NW) (We had to drill our hole larger, so if you dont have a tool to do this they have some that are smaller in diameter with a bigger hole.)

n. (12) OPAL 3-3/4″ DIAMETER X 4-1/8″ HEIGHT WITH 3″ FITTER ROUND BOTTOM CYLINDER TUBE (GLC304)

o. (12) 22-10 Crimp Sleeve

p. (2) large wire nuts

q. (2) Medium wire nuts

r. (1) Wire stripper/cutter

s. Lamp wire

*dependant on the height of your ceiling

While this project isn’t horribly hard (now that we know the right way to do it) it’s definitely not on a beginner DIY level.

You are going to start by assembling your short arms (these are the arms without the bend) using the 8” brass pipe (a.), the spoked holder (d.), and the metal base for the socket. (Make sure that once everything is assembled you tighten the small screw on the socket base.) This will keep your entire socket from unscrewing when you are changing the light bulb.

Next you are going to assemble the longer arms using 2 of the 6” pipe (b.), the spoked holder (d.), the metal base for the socket (e.) and the friction swivel (i.)

Take apart the friction swivel (dont lose the little bits!) and attach each side to the brass pipe.

Wire your socket by checking for the textured edge on your lamp wire. The smooth one is hot and will be connected to the gold screw inside your socket. The textured edge is going to be connected to the silver screw.

Then feed the other end of the wire through your socket base and brass tube.

Attach the socket to the base.

When you get to the friction swivel you will have to split your wire to go around the post in the middle (I just split mine from the bottom, up to this point).

Reassemble the swivel using all the little parts that you didn’t lose (because you are AWESOME!!)

I didn’t tighten the screw down all the way until I was completely done with the light (it made things a little floppy) but it gave me a little more play with the wire.

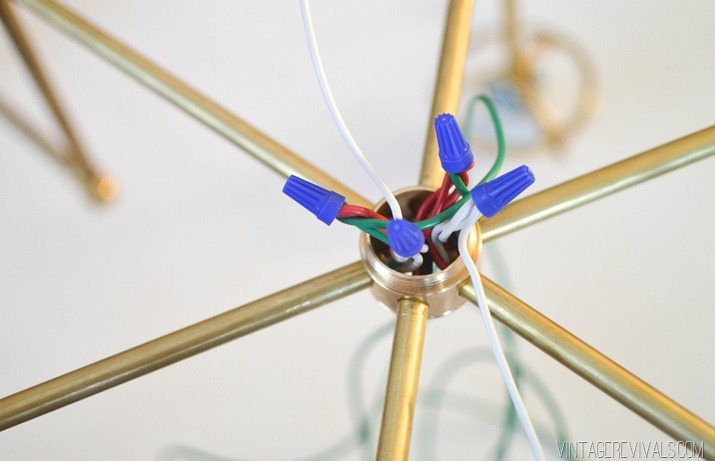

The next step is connecting your short arm and long arm to the hub and adding a 3rd wire that will connect everything to the main body of the chandelier. This was hands down the most complicated part of the entire light.

So here is what I learned.

Starting with the fact that the wires in this picture are WAY too long. But it is all I had to show you so sorry about that ;).

Make sure that the wires that are coming into the hub are on the same sides (hot, hot, and hot, neutral, neutral, and neutral) this will give you a little more room because they aren’t crossing over each other and adding more bulk to the situation.

Cut and strip the wires as short as you can while still being able to mange them (I think ours ended up about 1/2”-3/4” long) Twist the wire together and clamp it with a wire clamp (we had to trim a small amount of the plastic off of the edge of the wire clamp)

Lay it in as flat as possible. Once you have both of your wires clamped and sort of inside, gently pull on the 3rd wire (it is still exposed at this point, it hasn’t been covered up by the brass tube) and suck everything inside the little chamber.

Then add the cap and the screw plug.

Thread your 3rd wire through an 8” piece of pipe (a.) and connect it to the main body of the chandelier (f.) The body of the chandelier is an egg shaped brass piece that screws apart. When it unscrews, the piece with all of the holes is the bottom section. (This is a mini version)

Repeat for all 6 arms. When you are attaching them make sure that they alternate which arm (long or short) is on the top.

Once you have all of your wires in the main center hub take all of the hot and twist them together, adding one more long length of wire. This will be the main wire that runs up the stem to the ceiling. We found that it worked best to twist one group and then after the wire nut was on to tuck it down inside so that it was out of the way before twisting the second group.

To assemble the stem that comes out of the ceiling you are going to use the 12” pieces of pipe with the straight couplings. The amount that you need is based entirely on how high your ceilings are and how low you want your light to hang. This will attach to the hole in the top of the upper body section. The bottom section has a larger (1/4”) hole that you will cover up with the screw plug.

Add the large screw ring for the canopy (it comes attached to the hang straight coupling), the canopy, then the hang straight coupling and the cross piece in that order. Tighten everything up. I mentioned above that the canopy that we ordered had a hole that was too small. We used a hole saw that we had left over from this project to make it bigger.

Now comes the fun part. MAKE SURE THAT YOU TURN YOUR BREAKER OFF BEFORE YOU WIRE YOUR LIGHT! (yes that was me yelling, it is critical.) Attach it to the ceiling with the cross bar, wire it to the house wires and bring the canopy to the ceiling and tighten the screw ring. Dont attach the cross bar first, and then try to screw the light into that, it will just twist your wire up. Get the hang straight attached to the cross bar first.

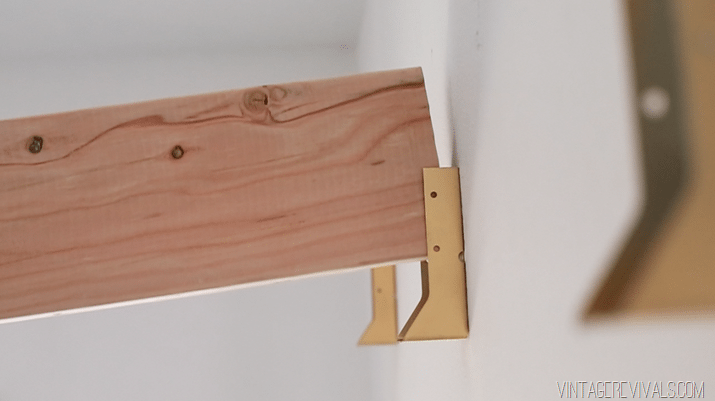

Apparently the ceiling beams are good for more than just looking awesome. How’s that for MacGyver?

When everything is wired, tightened and light bulbs are in, flip your breaker back on and cross your fingers that everything went smoothly!

The last thing is to tighten the screws on your swivel elbows, and finish it off with the glass shades.

If you make it through this entire tutorial, you are a rockstar!

So what did I learn rewiring the same light 15 times?

The first thing that I did was try a different type of wire because lamp wire was super thick. Even though it had a good amount of insulation on it, it was no match for the sharp edges of the pipe. Lamp wire was the only kind (I tried 3 different varieties) that didn’t have the coating stripped off of it. Go with lamp wire.

When something seems too small, that is because it is. The original main body of the chandelier was teeny. Too teeny to fit 6 wires into. Trust me I tried.

The bigger one that the final light ended up with was SO MUCH BETTER.

The last thing that I learned? The projects that push you to your breaking point and you hang in there and dont give up, usually end up being your favorite.

We’re thinking of adding them to the shop, so stay tuned!

Dont miss the Shop My House sale that is happening over at Joss and Main!!