Find me one person on this planet that doesn’t love a good sliding barn door. Go ahead. Its just not possible. They are like puppies. Impossible to resist.

The sliding door in Alicia’s Office was the first must have element that we decided on. Bi-fold doors were not her friend, and they aren’t yours either.

There are 2 main problems that people run into when lusting after a sliding barn door. 1. The hardware is expensive. 2. They are heavy. Like watch your toes if you want to keep them, heavy.

So after a late night brainstorm sesh I came up with the idea of a sliding screen. When I tell you this thing is light, I mean, me, the weakling with chicken arms can pick it up myself. Easily.

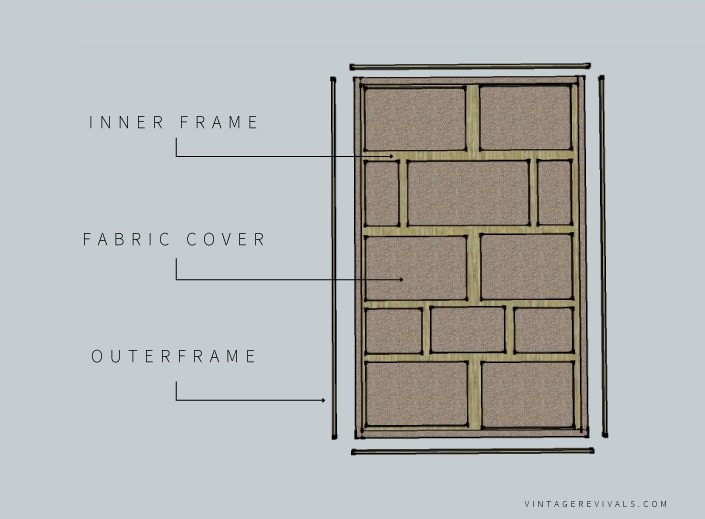

The secret is that behind that awesome fabric is just a frame. Nothing solid. When I say nothing solid, I don’t mean sturdy, I just mean not full of wood and weight.

Here is what you see:

And here is a sketch of what it looks like behind the scenes.

Its like magic!

Now, no 2 houses are the same, so I am going to tell you exactly what you need to know to make your own, and custom fit it to your space.

To start you need 3 measurements.

The width of your wall (or how far you want your door to be able to slide) stud to stud.

The height of your ceiling.

The width of the closet opening.

Supplies you will need:

Tools:

Miter Saw (or chop box)

Drill

Stapler (doesn’t need to be fancy!)

Nail Gun with Finishing Nails

Supplies:

**When you are buying your lumber, get the length that is most compatible with your ceiling height. For example our ceilings were 8 feet high so I bought 8’ boards. But if your ceiling is 11’ high and you want the door to go all the way up, you will need to buy boards that are at least that long.

1×2’s for the inner frame. For a door that measures 86×55 we used (10) 8 foot boards. These boards are extremely inexpensive (we are talking $2 each) so it is better to buy an extra or 2 than to have to go back.

1×3’s in Premium Grade wood. This type of wood is located by the molding and is more expensive, but it is much nicer quality that building grade and it is going to show. For a door that measures I bought two 8’ boards and two 6’ boards.

Fabric. I used an old table cloth and some clearance muslin from the fabric store. You can buy upholstery fabric (it usually comes in wider widths), a sheet, a table cloth, or a combo of all of them!

(3) Eyehooks

(2) 1.5” Fixed Rolling Casters

(2) 1/2×2”Pipe Nipples

(2) 90 degree 1/2” Elbows

(2) 1/2” Floor Flanges

(1) Length of 1/2” Conduit Pipe that is the same as your stud to stud measurement. You will most likely need to have this cut and threaded to the right length. Your friends at Home Depot will do this free of charge!

(8) 2” Hex bolts. These are going to attach the floor flanges to the wall. In all reality, 4 will connect to the studs and 4 will fill the other holes to make it look pretty. (Just keeping it real!)

Screws to build the inner frame work. We used Kreg pocket screws (without drilling the pocket holes) and they worked amazingly. Because of the way the threads are they don’t split the wood you are drilling into.

Ok! Here is how you do it!

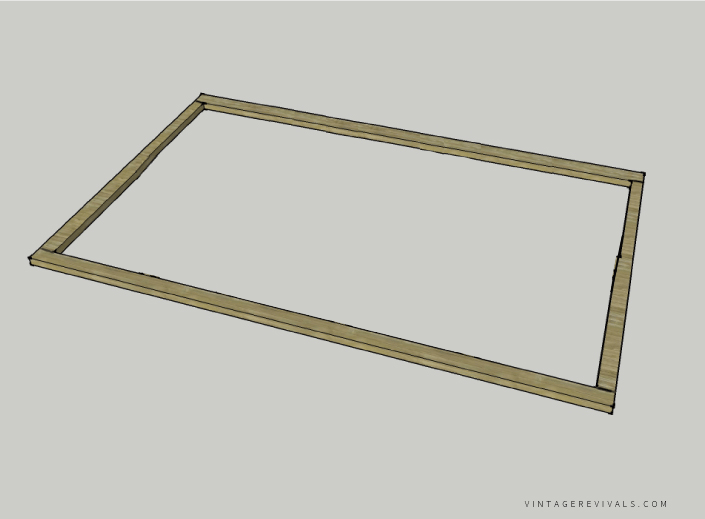

Start by building the outside of the inner frame. You want your door to be at least 6 inches wider than the width of your closet (measurement #3) and be 10 inches shorter than your ceiling (this will give you a little bit of wiggle room during installation!) When all is said and done, the door will sit about 6” below the ceiling, not 10”)

Drill a pilot hole into the first board. Using self drilling screws, screw them together. It is a godsend to have 2 drills for this process. This is the technique that you will use for the entire build.

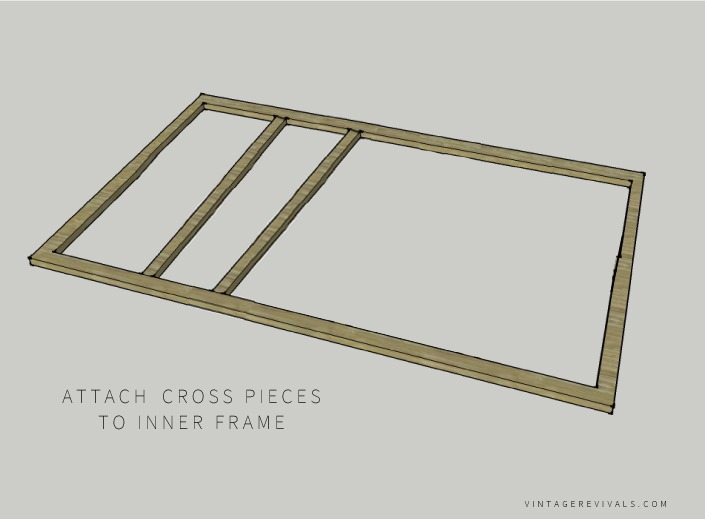

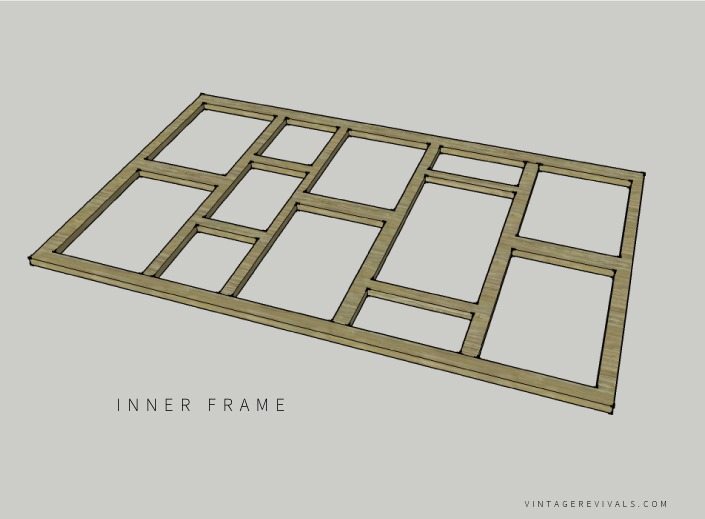

Once you have built your frame, you are going to attach cross pieces that run horizontally inside it. When you are measuring for these cuts, just make sure that you are measuring the inside of the frame, Double check that they are level (its not like anyone will see them, but it will make your job easier down the road!) We attached 4 boards, about 15 inches apart. Once again, unless you have someone living inside the closet you wont see these, so guestimations are a-ok with me!

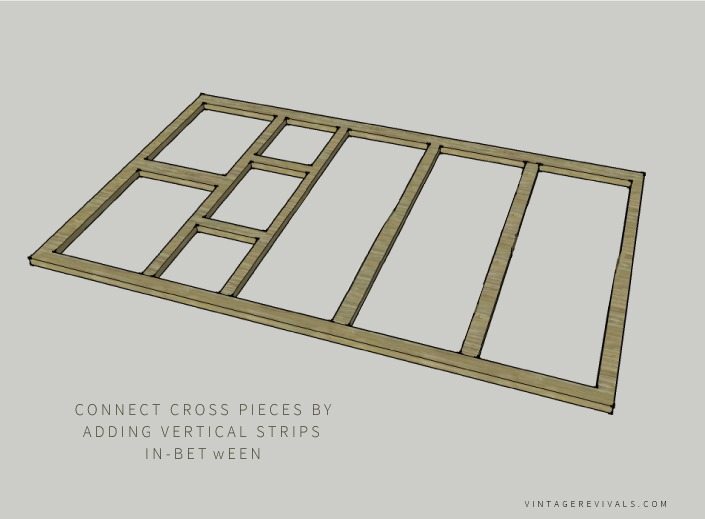

Once you have attached your 4 cross pieces, you are going to attach vertical pieces inside them. If you guestimated the distance between your horizontal pieces just measure before you make these cuts. Stagger the vertical boards to give it more strength.

That is it for the inner frame! Pretty simple right?!

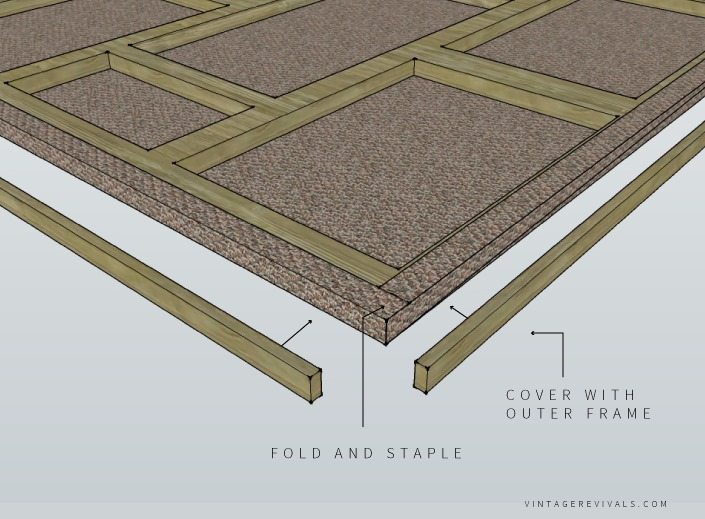

Next it is time to add your fabric. The design on my door has a large stripe in the center. So naturally it needed to be centered on the door. I marked the center point on the wood, and on the fabric, and lined those up before I started stapling (also make sure that your stripe is level!)

Staple a few in the center area on opposite sides, and then switch to the top and bottom and staple there. By rotating where you are stapling, (this is the technique) and doing the whole thing at once (as opposed to one whole side at a time) you will keep your pattern straight and help with bunching.

Trim off your excess. Just a side note here. I had a TON of excess fabric because it is easier to staple and then cut, than it is to measure, cut, and then staple, and then cut again. (You can see how much was left in the bottom of this picture!)

Once your fabric is on, it is time to attach the outer frame.

The outer frame is made out of the nice premium wood. Measure the short side of your door (top and bottom) and add 2” to that number. You are adding 2” to compensate for the width of the long sides . If you want you can miter your corners, but we didn’t, and it sort of looks awesome.

We used a piece of scrap 1×2” to fit the outer frame. By putting it on the front of the door, and then lining the outer wood flush with it, it gave us a 1” lip along the front.

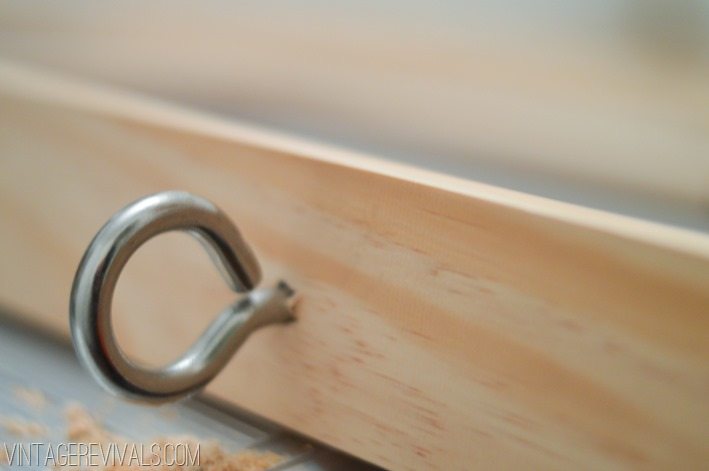

Measure in 8” from each end, and 1 1/2” from the front of your door and mark. This is where your eyehooks are going to be placed. Drill a large pilot hole that goes through the outer and inner frames and screw the eye hooks into place.

Center your cute little fixed caster wheels on the bottom of your door. *Important little side note. You don’t want wheels that can turn and move. Your door will get wonky faster than you can say “I HAVE TO GO TO HOME DEPOT AGAIN!?!” So fixed guys are your friends. Got it?

To mount your door you will need a helper. Maybe two.

Start by marking where your studs are. Mark where the ENTIRE stud is. Both edges. I promise you will thank me later.

Start by assembling your advanced wall mounting device. Or brackets. Whichever you prefer.

*Just a friendly reminder, the fittings above are 3/4” because that is what I had on hand. You will be using 1/2”.

Put the pipe through the eyehooks and attach both ends of the pipe to the brackets.

Move the door into place.

Before you start attaching the hardware to the wall you need to make sure that the door is resting on the wheels. Not the eyehooks. The eyehooks guide it, but the wheels hold the weight. Make sense? Try to center the pipe in the eyehooks so that it is sort of floating there. It makes things quieter too!

Now this part is going to make you want to kiss me. Probably on the mouth. Its fine. Remember how you marked both sides of the stud? You are going to turn your floor flange until 2 of the holes are over the stud. Because pipe cutting and tightening are not an exact science (obviously you want it to be as tight as you can get it, but my husband can usually get a few more turns than I can) this leaves a little wiggle room. You just manipulate where the screw holes line up by turning the flange, as opposed to trying to cut the pipe 1/4” shorter. So smart right?! Pucker up!!

Mark where your holes need to be predrilled. Predrill (obvs) and then attach the brackets with hex bolts.

This is a FANTASTIC, inexpensive way to get the look of an on trend sliding door, without the cost, or the headache!

If you are wondering what it sounds like and see how easily it glides, check out this video. (Its near the end)

Need more awesome ideas? Check out the full room reveal here, and the tutorials here!

I am so in love with this door! So much, in fact, that I couldn’t wait to build my own after you posted yours. I just couldn’t wait for the tutorial! I made the frame with some old 2×6’s from my dad’s barn, and since it needed to be double sided I wrapped a drop cloth all the way around and stapled, just like what you did. Then framed out with 1×2’s, added the wheels and eye hooks and bam! A Mandilicious sliding door for my room! Thank you SO much for this amazingly affordable, unique door. Everyone is super impressed with it, and of course I tell them I saw it at Vintage Revivals 🙂 Now if I could just decide what to paint on it! https://www.killerbdesigns.com/wp-content/uploads/2014/05/san-bernard-bonus3.jpg

This is genius – love it!

My husband and I just made a sliding mirror for our closet…I don’t know what it is about moving something on wheels but it makes all the difference!

So I’m seriously staking your page now for the Macie bed build. I’m redoing my daughters room next week. I am having flashes of a mattress on the floor…. This is a bad thing. Puleese! I am doing (stealing) your butcher block staining technique for the room

I’m pretty sure this is my favorite barn door EVER!!! So smart!! The heavy-factor is what’s held us back from installing a barn door in our home (our toddler would have no appendages), but now that I’ve read this, the wheels are definitely turning… 🙂

I love it! And I bet you could use panels of balsa or veneer if you wanted the wood ‘look’ without the weight and expense.

Maybe I missed it, but how did you put the leather on the fabric?

So so good!!!!

I freakin love this! I am going to show this to my fiance in the hopes that he can make one for each closet in our new home! WHOOT!

This is the best, Ive been looking a hardware for weeks and was just trying to figure out how to do it myself. This is just the ticket!

Hey there! We followed your steps and it turned out great. It looks much better and works much better than expected! The fabric especially came out nice! Can’t thank you enough for the inspiration and the instructions. We encountered a few MAJOR obstacles, all of which were of our own making 🙂 For those of you thinking about doing something similar, I’ve listed those obstacles below and explained how we fixed them!

1) Lumber dimensions, be they 3×1, 2×1, or 4×2, are NEVER actually the size they say. The 2x1s we got from Home Depot for instance were more like 1.5x.75 which REALLY threw off our calculations for fitting the slats into the inner frame and for the outer frame. This is tough, because if you don’t own a saw, you need to have the people at HomeDepot cut all the lumber to the exact length you need before you leave the store, so get ready to do some math at the store before you leave.

2) The discount 2x1s for the inner frame were, as stated before, barely .75 inches thick. We could have gotten higher quality/more expensive 2x1s that were more clean cut, but these were out of our price range. The .75in thickness made using wood screws impossible because there are few screws 2 inches long and skinny enough not to split wood that thin. We ended having to pre-drill then hammer in a nail for EVERY inner-frame to inner-frame attachment and inner-frame to outer-frame attachment. It took forever and was really tedious, but it worked.

3) We learned at the very last stage that our stud finder had misled us into thinking there were studs where there weren’t. We only had about 1.25 inches of drywall to work with, so we bought small, stout screws, wall anchors for the drywall (which we had to snip down to size so they’d fit), and washers so that the screw heads would catch the flanges. The important thing is that the weight of the door is 100% on the wheels. If the door were hanging from the pipe, it definitely wouldn’t have worked.

Thanks again!

What was your cost? Looking to make 3 of these!

Hi Mindy thanks for this step by step instruction. you are the best. I will be visiting your sites often.

i have 3 projects in mind.

– sliding door for bedroom closet

– living room wall- one wall done with recess wood logs

– redo kitchen. which i will need to hire someone professional. tho i want the shabby look so i think i probably will do some of the work myself.

Mochi.

Hi! Thanks for this awesome guide. I just wanted to give a word of advice, based off of what jay mentioned above about the common boards being smaller than their nominal size. I would recommend saving the cutting of the short vertical pieces until the very end. I cut all my boards first, and ended up having to recut the vertical ones because the ones I had cut at the beginning were too short.

As for screws, I used GRK brand (https://www.grkfasteners.com/index.php/en/products/rt-composite/rt2) #8 x 3-1/8″ that I picked up at home depot. I had a couple splits in the boards, but nothing serious, and these screws were really nice, as there was no predrilling necessary at all. I’ve got the inner frame built now, and am looking for fabric/inspiration on how to finish it!

where did you buy your materials?

Bravos! So going to do this!

Wow, what a great project. Thanks so much for the idea!! Love it

Hi, I was just wondering how the sliding door has held up over time? Thanks.

Kamille H

Just wonding if anyone has had issues with the pipe sagging in the middle. I really want to do this but for a 9 foot closet. Im not sure if that would be too long tho.

It shouldn’t be a problem as long as the pipe isn’t actually supporting any weight…

I love your idea!

I am planning to make 3 doors to hide a 14′ wardrobe and i have a couple of questions.

I suppose you used a lot of staples to make the fabric stay in place. Is there a way to hide the staples or are these visible?

Do you think that a guide at the bottom would make the sliding better, preventing the inside-out moving of the door?

Thank you for the great sharing!

I had to lol at the “kiss me, probably on the mouth thing…” but when I thought about it I did!!! This is a genius idea and perfect for my projects…I am try to make sliding doors for two lil ones (granddaughters) in their room but once I tweak this to hold their chalk board on one side and my plans to do burlap for their art work on the other, this is gonna be perfect and the hardware fits in perfectly with their hanging beds and closets I built!!! Thanks a bunch I woke up this morning looking for the perfect pin and here you are ?

Thank you, thank you. I will be building mine this weekend.

Does it make much noise when sliding? I want to build this in our apartment but my girlfriend thinks the metal eye hooks on the metal pipe is going to make a grating noise.