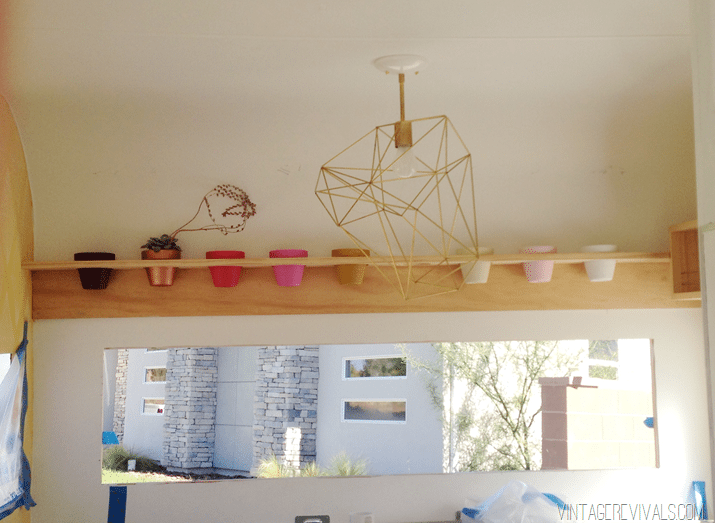

Dudes! We are overhauling a 1972 Bell Travel Trailer! Follow the entire series from the beginning here! Huge thanks to The Home Depot for sponsoring this post!

It seems that with the Nugget, even the most well intentioned projects have gone awry. And OF COURSE that is the case with the door. Could we have just painted it to match the trailer? Sure. How about adding an accent color with it? Obviously. How about figuring out how to replace the aluminum with wood panels? Errrrr.

That was plan #1. From what we could tell, the door frame was in 2 pieces, an outer frame (that you could see) and then an inner piece that pushed the aluminum flush to the outer frame. So I thought it would be a great idea to take the door apart and find out. (Do you know where this is going?)

Its going here.

And here.

And here.

Oh, and of course here.

And then it took severe left turn into a brick wall and exploded.

The frame was in fact not 2 pieces, just 1.

So we figured that we were this far into it. We might as well try to use the table saw to cut a bigger groove in it (in hopes of fitting 1/8” ply inside) which just might have worked if Court didn’t accidentally cut through the entire lower 1/3 of the frame.

That was fun. Its not everyday that you get to ruin something irreplaceable.

In hindsight I would totally have just taken the door off and sold it on Ebay. But you know. Sometimes you just have to try and see if what you have in your mind is even possible. You know?

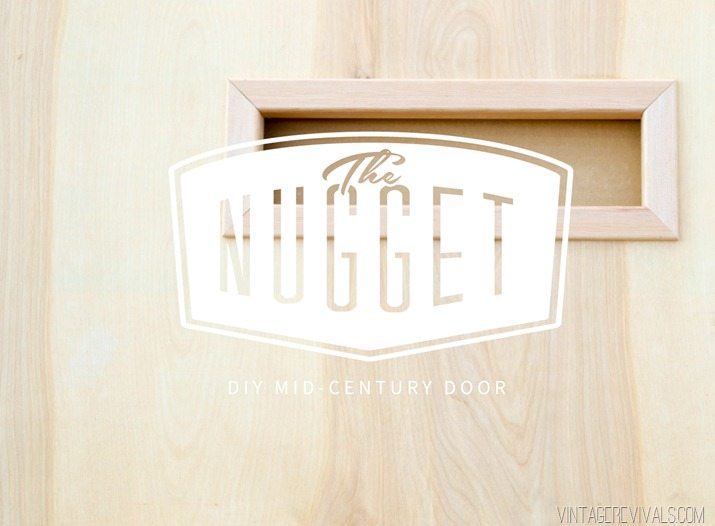

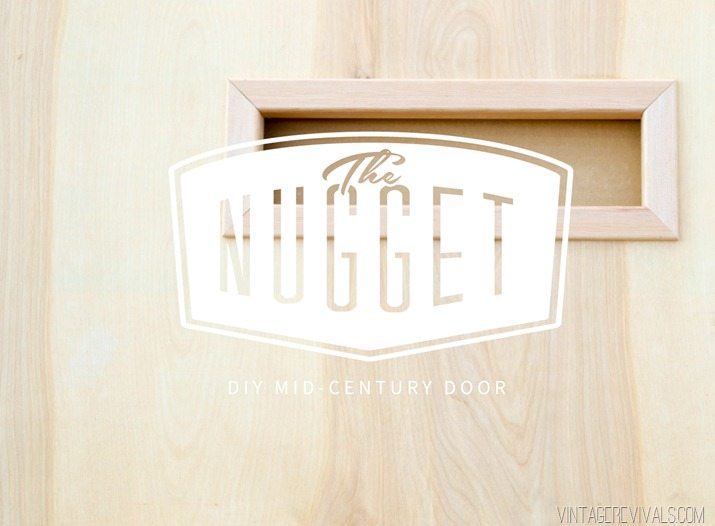

Now that we weren’t working in the parameters of the old door, and could truly do whatever, I decided that a mid century esq door would be just the ticket.

The original plan (well…the second original plan) was to make a Dutch door because that would be FREAKING AMAZING. But it was not to be. The hinges were built into the actual door frame and that was not something that we were willing to replace. So a simple single door was the winner! (But mark my words. A Dutch door IS in my future.)

Before we go any further lets chat about weight, because that is the biggest factor that you have working against you while you are working on a trailer. The original door was surprisingly heavy because of the thick glass window. (We decided to use light weight plexi for our windows) but we still wanted to make the door as lightweight as possible, so we made it hollow-ish.

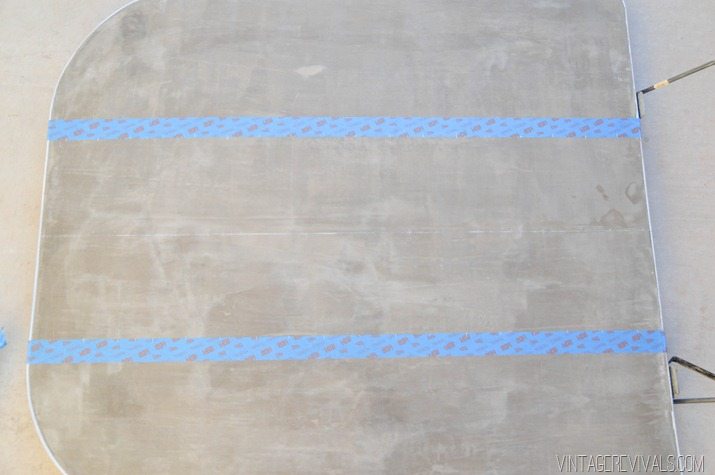

To start we measured the width that the door needed to be, and subtracted 1/2” to compensate for the 2 pieces of 1/4” ply that make up the face and back of the door.

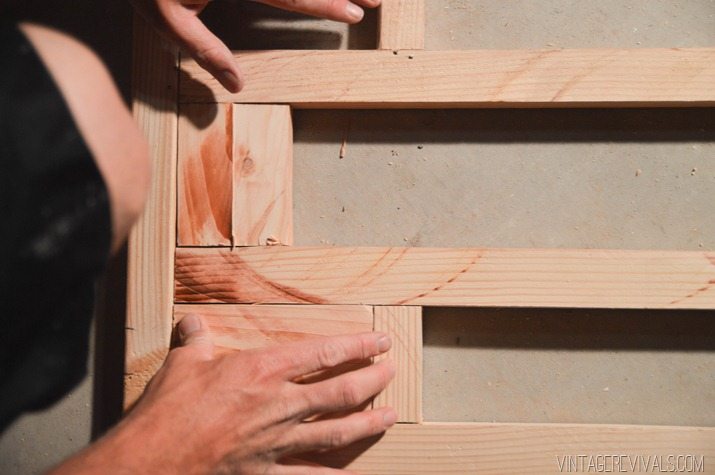

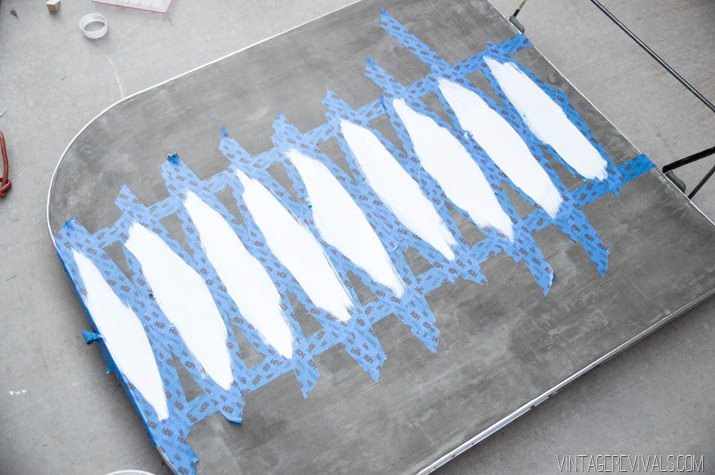

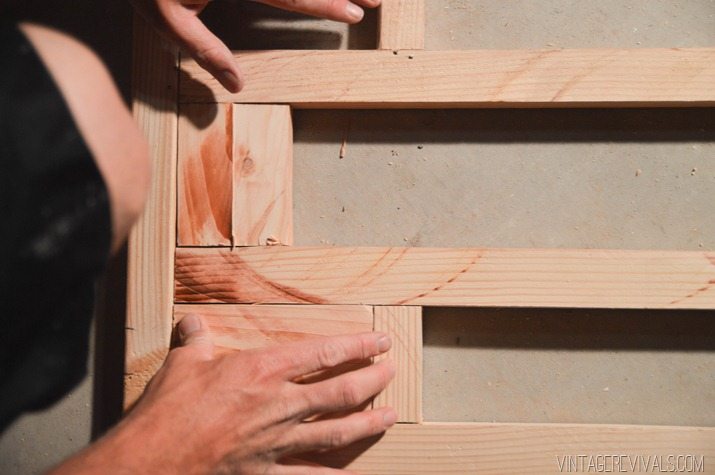

We started by building the inside frame

And then added cross pieces that made up the top and bottom of the window. We put in the small vertical pieces that makes up the other side of the window.

Last we put an extra piece where the door knob and lock goes so that it is really solid in that spot.

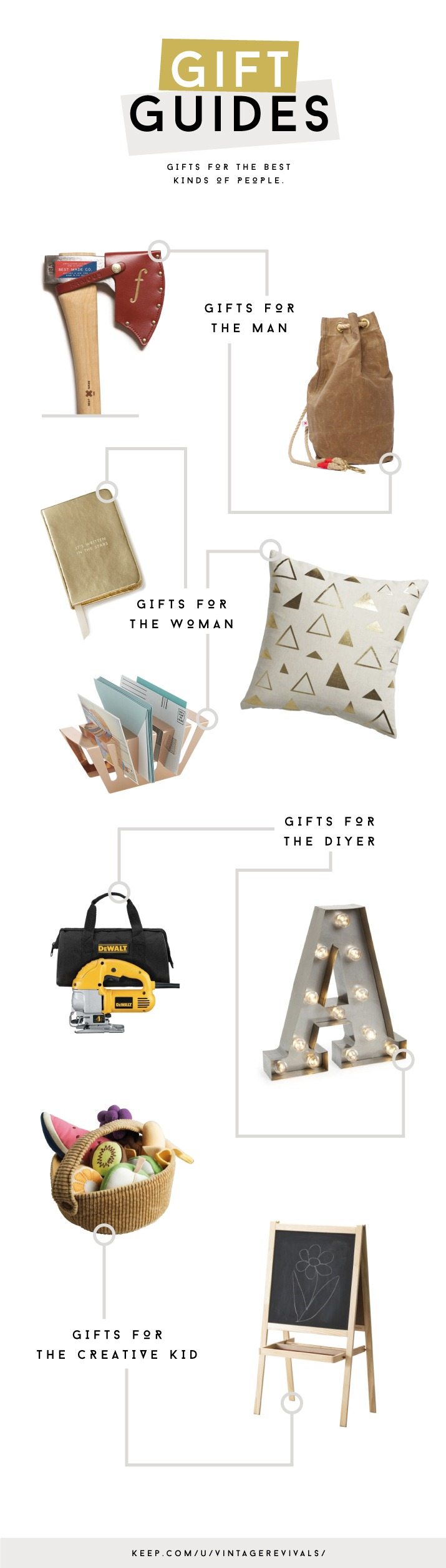

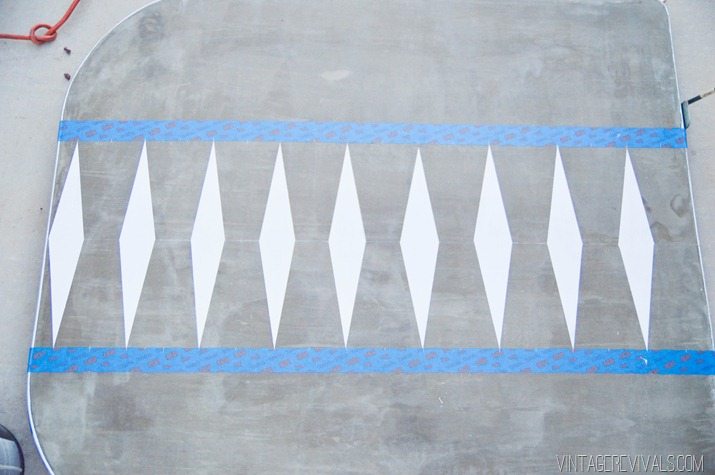

Then we measured and marked the pieces of 1/4” ply and used a jigsaw to cut the window holes out. This is our jigsaw. It is basically the 3rd member of our marriage.

(When you are doing a project like that and you want the wood to look nice I would recommend seeing of your local Home Depot carries Purebond Plywood, it is beautiful!!)

We decided that instead of nailing it on we would try our hand and gluing and that way, if it needs to be attached tighter then we could nail it. Good news, the glue is AWESOME. We used Titebond III because it is waterproof and has amazing reviews.

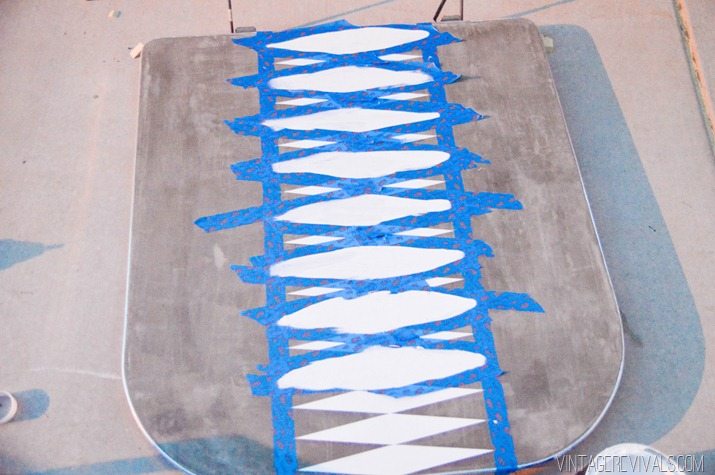

We glued one side and let it sit for 24 hours before we flipped it over and glued the other side.

Once everything was dry, we measured and cut the plexi for the windows with a fine blade on the jigsaw.

The last step was to add the window trim that actually holds the plexi in place and finishes it off.

I debated on using white PVC as trim….

But ultimately decided that even though wood would be WAY more expensive, that it was the better choice.

We measured and cut all of the pieces at 45 degrees. While we were putting the windows in we realized that we had to trim one side of the window trim down the width of a saw blade, so we really quickly (and very carefully!) ran them it through the table saw.

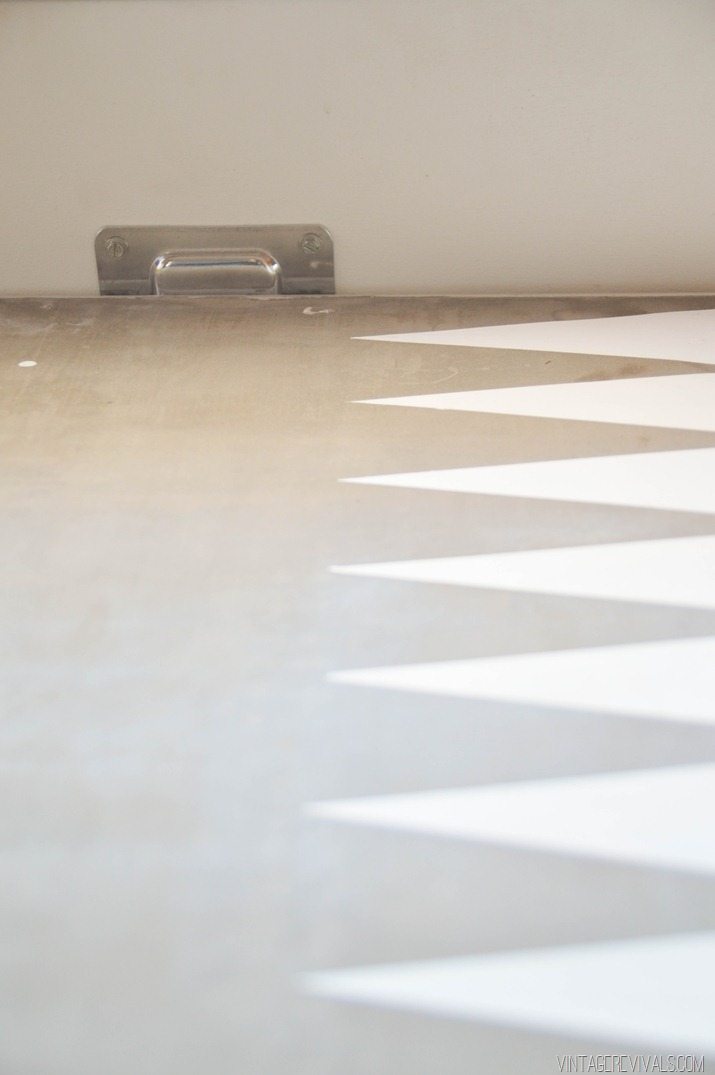

Before assembly we put a few coats of Helmsman Spar Urethane on the door and trim pieces. Spar Urethane is ideal for outdoor pieces and has UV protectant in it. It is really easy to work with too, so that was a bonus!

When you are working with Spar Urethane, you will want to lightly sand between coats with extra fine steel wool, and then wipe it down with a tack cloth. We did 3 coats on our door.

After everything was dry we assembled it and glued with Titebond 3.

I was SO grateful to learn that Home Depot sells a door hole drilling kit. Unfortunately because the front of the door has a 2” overhang we weren’t able to use it the way that it is intended. BUT we still used all of the parts and saved a bunch of $ buying it as a kit.

After deciding exactly where we wanted the knob, we drilled a pilot hole to get started. Then we used a 2 1/8” hole saw to bore the hole into the door.

We did this on both sides so that it didn’t tear through the back end and splinter the wood.

Then we used a 1” spade bit to drill the hole into the side of the door for the locking mechanism.

I am SO thrilled with how this door turned out! WAAAAAAAY better than the one that I had imagined originally.

I seriously want to do this on a bigger scale for my front door. I LOVE how it turned out!!