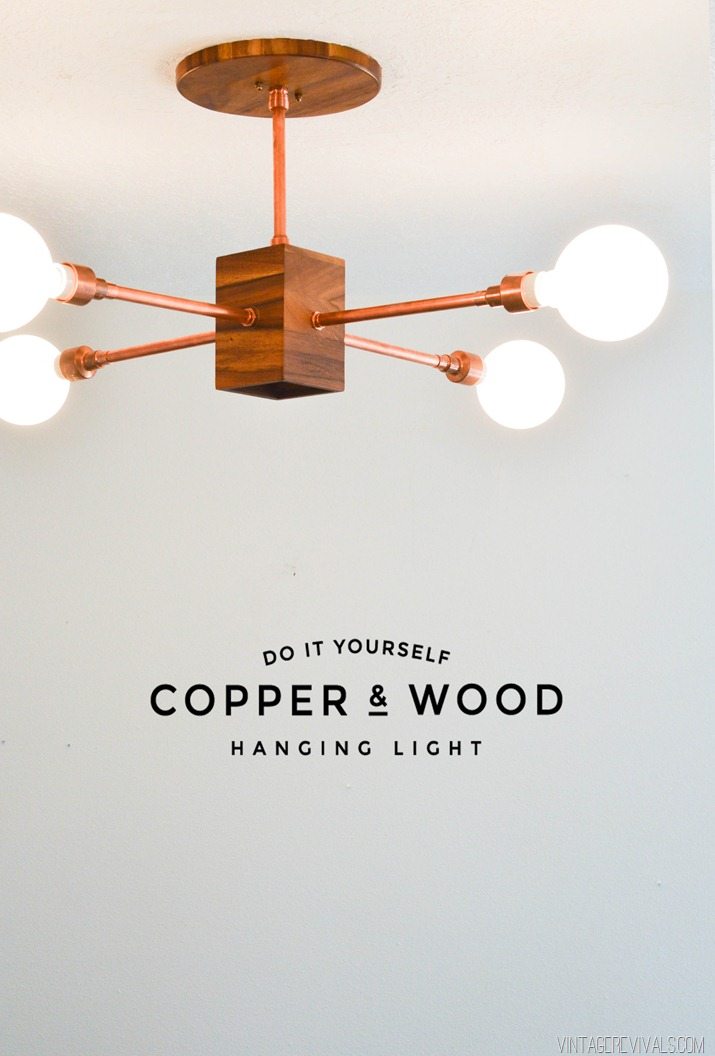

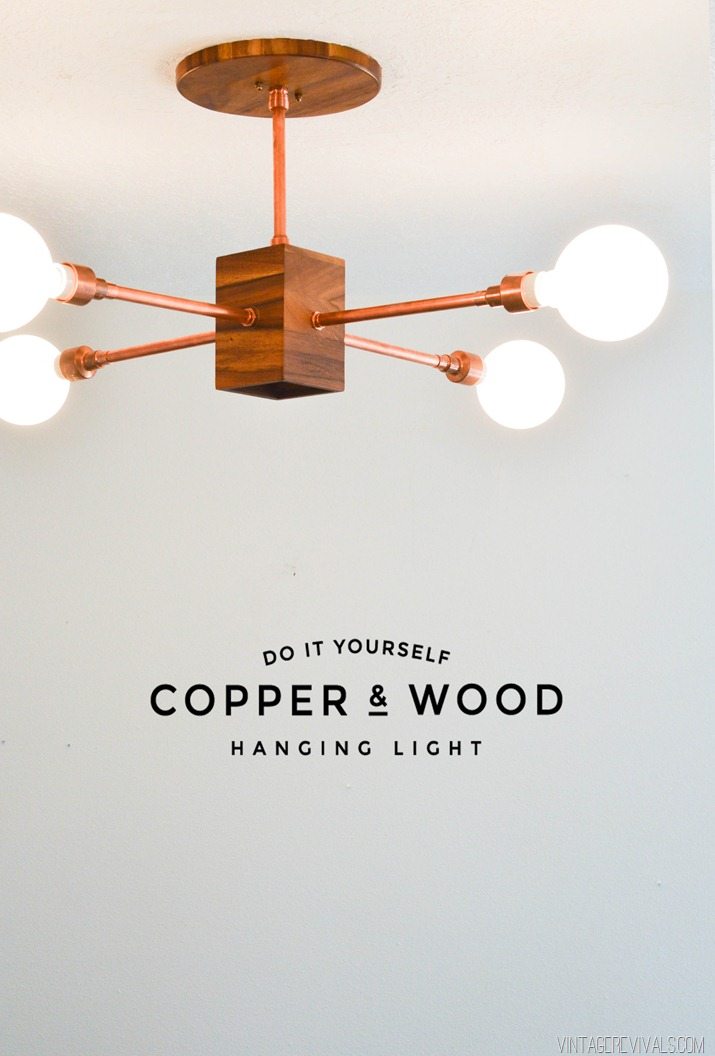

Do it yourself lighting is one of my favorite types of projects to tackle. Lighting (well beautiful lighting) can be seriously expensive. But guess what?! It doesn’t have to be! There are so many cool components that you can find around your local hardware store that can be put together to create a serious show stopper.

Originally the plan for the lighting in Ashy’s room was to hardwire this light. I mean, the design is perfect for the space, right? We got it installed and had a problem.

A one light bulb problem.

This room is so ginorm that having a light with just one bulb was not cutting it. As I was problem solving different solutions (where to put wall sconces, lamps etc.) I realized that we really just needed a different light.

Just a side note, if you are at your local hardware store and you see a crazy looking lady in paint clothes, sitting on the floor surrounded by pipe fittings with a wild look on her face, just keep your head down and don’t make eye contact.

The great thing is that after the wild look passes, she probably has a pretty great plan.

Here is what you need: (I bought the hardware supplies at Home Depot and Lowes. Locally, Lowes seems to have a bigger selection of copper fittings.)

(4) ceramic light sockets

(4) 1 1/2” x 3/4” Reducing Coupling

(4) 3/4” x 1/2” Fitting Reducer

(4) 1/2” Threaded Adaptor Fitting (Male)

(5) Washers

(5) Pipe Nuts

(4) 10” pieces of 1/2” pipe

(1) 8” piece of 1/2” pipe (or measured to the length that you want your fixture to hang)

(2) 1/2” copper push-fit male adaptor pieces

(1) Threshold Utensil Caddy

(1) Threshold Bowl

12’ of lamp wire

Loctite 5 Minute Epoxy

Drill with 1/2” Drill Bit, and 3/4” spade bit

Start by taking apart the ceramic sockets. Right now, we just want the metal base.

Using your epoxy, glue it to the inside of the reducing coupling (make sure that it is straight!) Let it set for at least 5 minutes. (Be aware of any drips down the inside, they will cause problems when you attach your next piece)

Add a small amount of glue to the inside of your Reducing Coupling, push the Fitting Reducer into the bottom of it.

Add a small amount of glue to the inside of your Fitting Reducer and attach 1 of the 10” pieces of pipe.

Repeat 3 times. These are your arms!

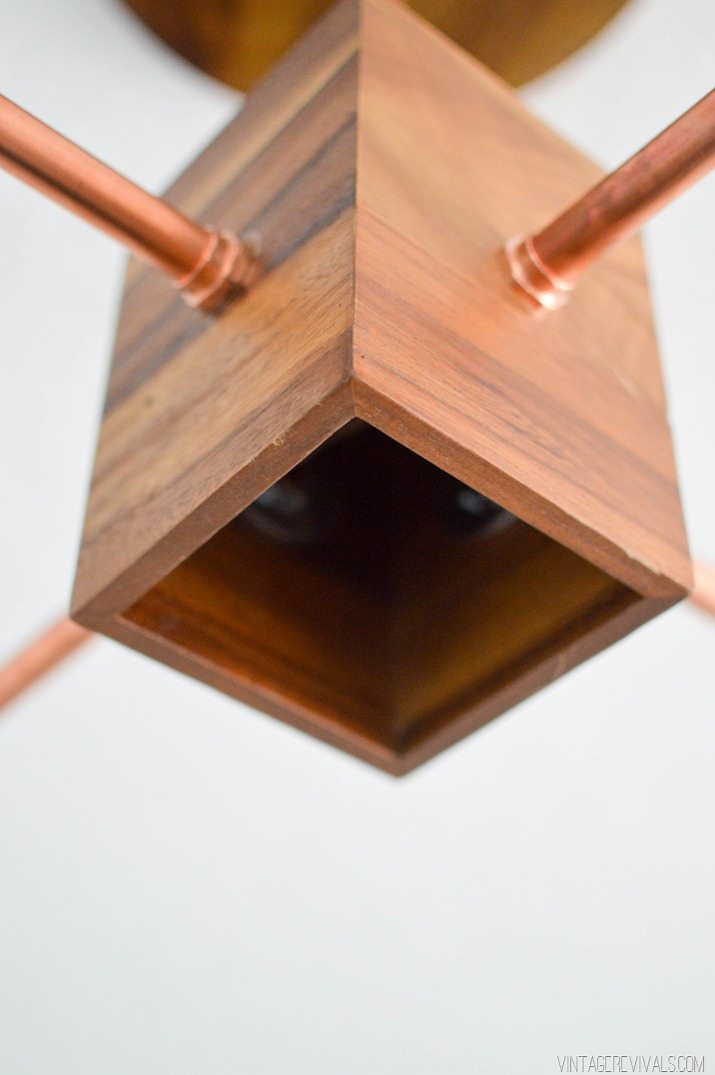

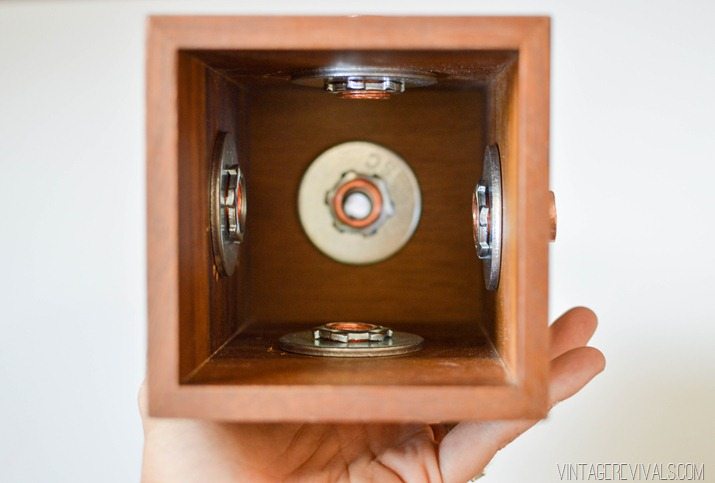

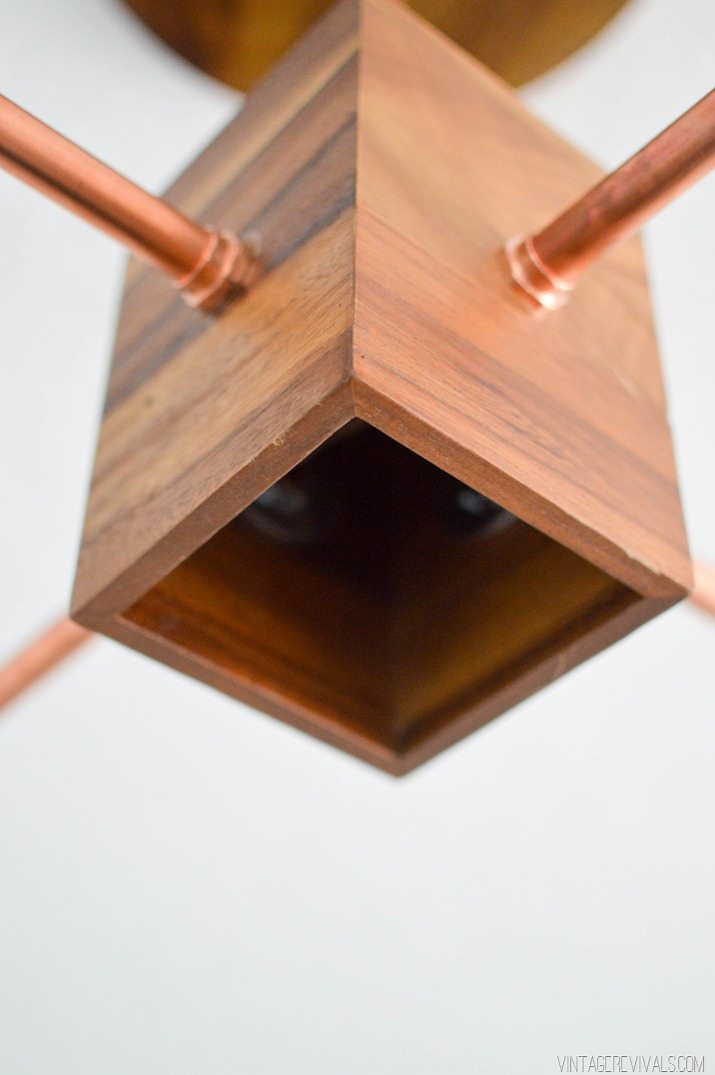

The heart of this light is a wooden utensil holder from Target (couldn’t find it online, but it is still in store). Originally I was picturing 2 wooden bowls sandwiched together, but I think this worked out to be significantly easier. Using a 3/4” spade bit, mark and drill a hole in the dead center of each side of your box. Even with a 3/4” hole, you will need to ream it out a little bit more so that the Male Fitting Adaptor will fit inside.

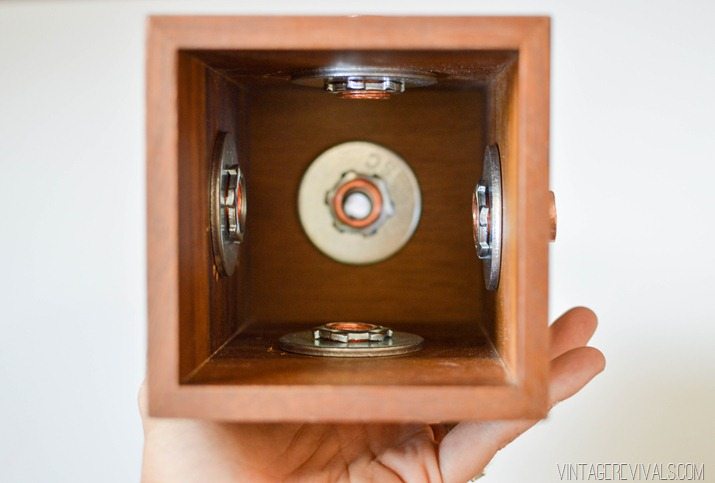

These were a little hard to hand screw in, so on some I used a socket wrench (you can see the mark that it left on the top of the box). Just be careful to not make your hole too big when you ream it, this adds a lot of stability to your arms. You are going to do this on all 4 sides, as well as the top. The only difference is that the top gets a Push-Fitting, instead of a simple adaptor.

Next, put your washers and nuts on the threads inside the box.

Attach the top piece of copper (mine was 8” long) to your push fitting.

Cut 5 pieces of lamp wire so that they are 20” in length (this will give you some wiggle when you are wiring) and thread one through each of your lamp arms.

Wire your socket according to the instructions found on the packaging (don’t forget to put the red rubber piece on first!)

Because we are making a light with multiple sockets, be EXTRA sure that you are wiring the hot lines to the same colored screw in each socket (i.e. all of the hot lines go to the gold screw, and the neutral lines go to the silver one.) You will be able to tell which wire is hot because there is a small ridge on the edge of that wire to differentiate the hot from the neutral.

When all of your arms are wired, put a small amount of glue on the inside of your Male Adaptor Fitting and push them on, so that the wire is INSIDE your box.

Using large wire nuts, join all 5 of the hot wires together (4 from the arms, 1 from the top) and all 5 of the neutral wires together.

Now its time to install!

We had to move the junction box so that the light could hang in the right spot of the room. Please please please for the love of all that is good in this world, DO NOT do this if you don’t know what you are doing. Hire an electrician to spend 25 minutes at your house. Ok?! When we moved the junction box, we left the electrical inside the old one and piggy backed the new wire from there. It is illegal to permanently cover a hole that still has live wire inside it. To disguise it (without making the ceiling feel like a land mine) we used a simple cover and put putty on it to sort of match the ceiling pattern. If you look at it, it is very clearly there, but if you aren’t trying to notice it, it doesn’t jump out at you. The most important part is that it is a temporary solution and can be spotted and opened up easily.

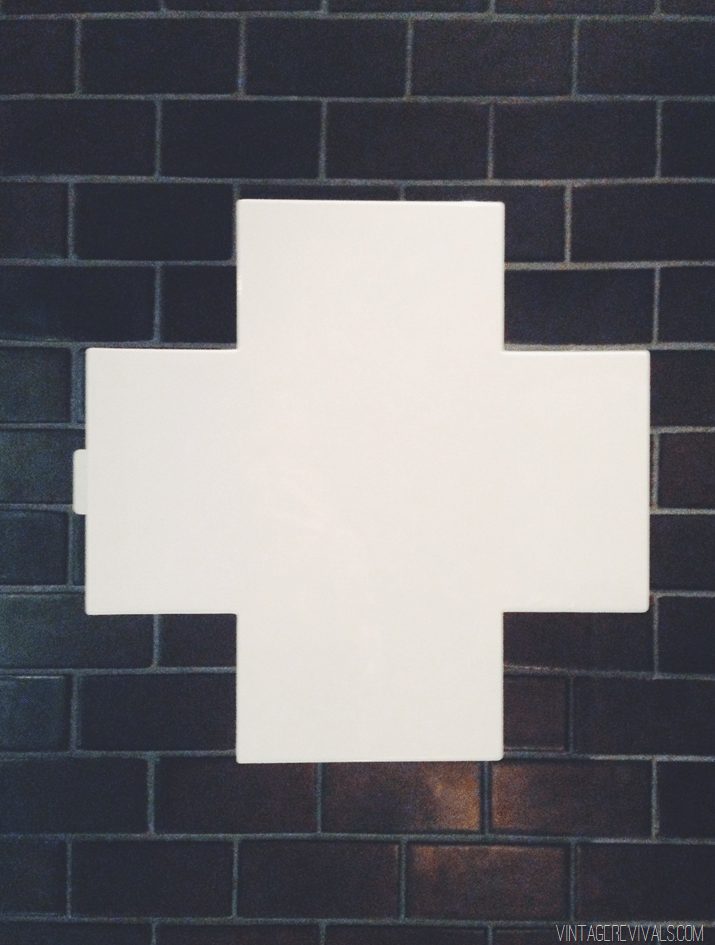

For our ceiling mount, I bought this bowl from Target, and used my table saw to cut most of the sides off. I left a small 1/2” lip. If you don’t have access to a table saw, you could use a wooden plate, or even a regular cover and spray paint it copper.

Drill a hole in the center of your mount, and attach the second Push Fitting as well as the washer and nut to the opposite side.

Measure on your junction box the distance between the screws, and drill into your mount. If you are using screw caps like we did, you will need to have them hanging down before you can mount your light (if you look closely in the picture below you can see the screws.

This is where you wire your light. No pictures, because I was the one holding it up, but don’t forget this minor step.

Put the mount on the ceiling with the screws coming through the holes, and attach screw caps. I was a little nervous about just having the screws holding the light up, but after talking with an employee at the hardware store and having him point out giant hanging lights that had the same style mount, I felt so much better about it.

(The pic below was of the dry run, you can see that there are no wires coming through. When you are installing it for real, the light will be hanging down.)

Once the ceiling mount is installed and wired, push the copper pipe into the Push Fitting and TA DA! your light is done!!

I didn’t cover the hole at the bottom because the wires are tucked up inside it so far, but it would be cute to put a piece of copper contact paper or something on the bottom if you feel like it needs it.

Questions? Leave them below!

.

.